Purdue University 1997 Swine Day Report

A.P. Schinckel and M.E. Einstein

Department of Animal Sciences

The amount of selection pressure placed on a performance trait relative to other traits is determined by its economic value relative to the other traits. The economic value of carcass leanness should be based upon current and anticipated future carcass merit programs. In the mid 1980's, pork processors were merchandising partially trimmed lean cuts. During the late 1980's and early 1990's, consumer demand for increasingly lean products was communicated via retailers back to the pork processors. Subsequently, pork processors focused on the production of a higher percentage of highly trimmed lean products.

In the early to mid 1980's, the economic value for backfat based on carcass cut-out and the weights of partially trimmed pork products was estimated at approximately 1% per .1 inch change in backfat thickness. Based on the production of highly trimmed lean cuts, the economic value for backfat increased to a range of $14.00 to $18.00 per inch. Recently, a value of $15.00 was estimated by the National Swine Improvement Federation (1996).

A linear economic value for a measure of carcass leanness such as percent lean, backfat thickness or loin eye area assumes that the value of each unit of improvement is constant over the entire range of pigs currently being produced. Implementation of carcass merit programs has resulted in intense selection for leanness by domestic seedstock producers and importation of extremely lean pigs from Canada and Europe. Currently, pork processors, industry leaders and seedstock producers are reconsidering the use of linear economic values for measurements of carcass leanness. Based on these concerns, an alternative curvilinear economic value for carcass leanness was developed.

Representatives of four major pork processors were confidentially interviewed as to their current and anticipated future carcass merit buying systems. Currently, one pork processor actually reduces the premium of pigs with less than .67 in. (17mm) backfat thickness due to an increased incidence of pork quality problems in extremely lean carcasses. One pork processor pays no additional premium for pigs under .60 in. backfat thickness. All four pork processors independently agreed on the following issues:

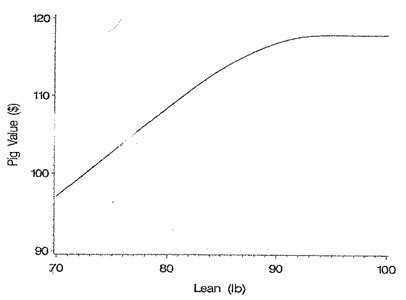

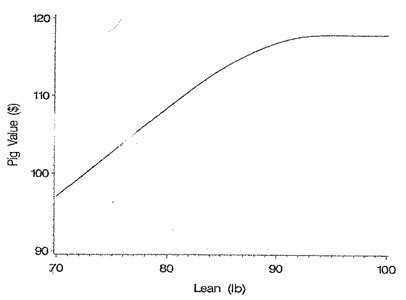

The current and future anticipated carcass merit systems were scaled to a common value ratio basis where carcass value = base price x value ratio. A base price of $112.50 was assumed for a pig of 84 lbs. of lean adjusted to a 180 lb. carcass weight (LBLEAN; 250 lbs. nonshrunk live weight; 240 lbs. shrunk live weight). The value ratio was transformed to a value index. The maximum carcass value index (1.00) was attained at 94 lbs. LBLEAN.

A combination of linear, curvilinear and asymptotic functions resulted in the best fit relating the carcass value data to LBLEAN. Carcass value can be estimated by the following steps:

If LBLEAN < 76.2 then value index = .8835063 + (.0097118 x LBLEAN)

If 76.2 ≤ LBLEAN ≤ 94.0 then value index = 4.480229304 - (.161187 x LBLEAN)

+ (.002245 x LBLEAN2 ) - (.000009831 x LBLEAN3 )

If LBLEAN > 94.0 then value index = 1.00

Value Ratio = 1.047815 x value index

Carcass Price = base price x value ratio

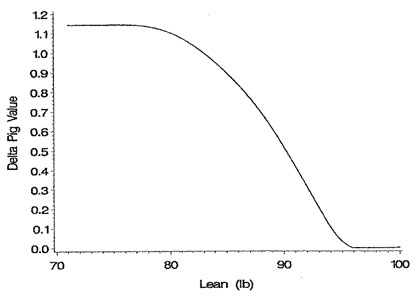

An example was calculated assuming a base price of $112.50 per pig ($62.50 per cwt carcass price). The relationship of pig value to LBLEAN is shown in Figure 1. The three functions result in a smooth curve. The incremental increase in pig value with each incremental increase in LBLEAN is shown in Figure 2. When LBLEAN is less than 76.2, each incremental pound of lean has a value of $1.15. The value of each incremental LBLEAN decreases as LBLEAN increases from 76.2 to 94.

These equations can be used to develop a curvilinear economic value for LBLEAN. The LBLEAN used in the carcass value calculations would be the breed mean plus the EPD for LBLEAN of the individual animal. The incremental value of increasingly leaner animals becomes smaller as the EPDs for LBLEAN increase. This prevents extremely lean, slow growing pigs (or family of pigs, especially with EPDs) from being favored over moderately lean, fast growing pigs. Thus, as pigs become genetically leaner, the selection indexes would place a decreasing amount of emphasis on measures of carcass leanness relative to all other traits.

In the future, pork processors will increasingly emphasize uniformity - only pigs within specified carcass weight and LBLEAN ranges will receive premiums. Seedstock suppliers must know the LBLEAN their commercial customers are achieving in order to refine their selection programs. In the future, seedstock selection emphasis for leanness must increasingly target the desires of pork processors which are based on consumer demand.

Figure 1. Relationship of pig value ($ pig) to pounds of fat-free lean adjusted to a 180 lb. carcass weight.

Figure 2. Incremental increase in pig value ($ pig) with each incremental increase in pounds of lean adjusted to a 180 lb. carcass weight.

Index of 1997 Purdue Swine Day Articles

If you have trouble accessing this page because of a disability, please email anscweb@purdue.edu.